The overall system architecture of intelligent manufacturing in the pharmaceutical industry can be divided into equipment layer, control layer, business management layer, and operation management layer. This issue introduces intelligent systems in the device layer and control layer.

device layer

The equipment layer mainly includes three parts: production process system, utility system, and automation control system.

Production process system

In the process of equipment selection, attention should be paid to the writing of User Requirements Specification (URS), especially the relevant requirements for technical evaluation. Attention should be paid to the data standards, interface standards, and communication protocols of programmable logic controllers (PLCs), distributed control systems (DCS), and human-machine interfaces (HMI) to ensure the interconnection and intercommunication of data between devices and systems.

In the process of renovating traditional production workshops, manual input of data or information should be minimized as much as possible, and data should be intelligently collected through sensors, intelligent instruments, and other methods. Conditional enterprises may consider adopting advanced process equipment such as industrial robots, unmanned guided vehicles (AGVs), visual recognition, and online inspection.

utility system

Enterprises should consider establishing a cluster based public engineering automation system, covering refrigeration units, clean room air conditioning systems, water systems, power systems, steam systems, etc., to comprehensively cover and manage clean environment control, water, electricity, gas, steam and other supply and scheduling operations in the pharmaceutical industry, in order to reduce energy consumption and improve production efficiency.

The construction of a cluster control system can consider using process control system technologies such as distributed control systems (DCS) and communication methods such as industrial Ethernet to achieve interconnection and interoperability of public equipment, and to carry out linkage control according to actual situations. On this basis, standard communication interfaces are reserved to provide data interfaces for data acquisition and monitoring systems (SCADA).

control layer

Data acquisition and monitoring system (SCADA)

The data acquisition and monitoring system (SCADA) is mainly used to achieve full data integration and solve the problem of data silos. The data acquisition and monitoring system (SCADA) provides data for other information systems, thereby changing the previous decentralized monitoring mode and achieving centralized control of each system. At the same time, the data acquisition and monitoring system (SCADA) can promptly alert for deviations and faults that occur during production operations, transforming post event management into real-time online management.

The data acquisition and monitoring system (SCADA) generally uses industrial configuration platform software for unified planning of the entire plant. Considering the performance requirements for future factory data collection volume and collection cycle, a functional sharing architecture can be adopted to configure data collection and storage separately on different servers, and to configure dual machine hot standby. Given the pharmaceutical industry's requirements for data integrity, reliability, and real-time performance, industrial real-time databases are generally used as the basic storage pool for enterprise information systems, providing foundational data for other information systems.

A data acquisition and monitoring system (SCADA) generally includes real-time monitoring of the production process, abnormal alarm recording, data processing and analysis, real-time data management and archiving, permission management, etc. Data processing and analysis are the core of the Data Acquisition and Monitoring System (SCADA), which consists of functional modules such as data acquisition, real-time database, event alarm, historical trend database, and historical data/event alarm dump. Meanwhile, consider configuring audit tracking functionality to ensure the traceability of operations.

automatic control system

The production process of pharmaceutical companies can usually be divided into two stages: raw material drug production and finished product drug production. The process control of active pharmaceutical ingredients is generally completed through a large-scale distributed control system (DCS); In the production of finished drugs, the equipment used in each process step is usually controlled through a built-in PLC system. These PLC systems generally come from different manufacturers and are independent of each other. With the continuous penetration and spread of the Internet and the new generation of information technology, the original relatively closed use environment of industrial control systems has been gradually broken, and the openness and interconnection are becoming stronger and stronger. The automation control system collects on-site control data and information through interfaces with distributed control systems (DCS) or data acquisition and monitoring systems (SCADA), and interfaces with manufacturing execution systems (MES) to achieve information flow interoperability.

The key components of the automation control system, such as power supply, controller, and network, can be configured with 1:1 redundancy. Equipped with UPS power supply and AC power switch to ensure the safety and stability of power supply, communication, and CPU. Realize time synchronization of all computer control systems within the local area network. According to GMP requirements, each authorized user has a unique identification code, password, and electronic signature, and the system can track and query the electronic signature and audit.

Automated control systems can use flexible batch formulas to control production processes. Based on the ISA-S88 standard, provide consistent standards and terminology, define physical models, procedures, and formulas, control batch process production, and manage the entire manufacturing process from raw material input to product delivery. Among them, batch control programs include unit programs, operations, and operation stages. By interacting with the Manufacturing Execution System (MES), the production parameters for different batches are determined and confirmed by the MES before being issued to the automation control system. The automation control system sends back data such as time, status, and process parameters to the Manufacturing Execution System (MES) to complete electronic batch recording.

Automated control systems can ensure special environmental requirements. Following the GMP management concept, we will establish an intelligent control system for the production environment and build an automated "one-stop" and cluster based public engineering control system to ensure the supply of energy, water and other resources and the control of clean environments. The specific content includes clean air conditioning purification system, clean area environmental monitoring system, personnel access control management system, video surveillance system, intelligent environmental protection treatment system, etc. In addition, an integrated workshop safety instrumented system (SIS) can be built to ensure safe production, based on a decentralized control system, using advanced, applicable, and effective professional calculation methods to improve the reliability of system operation.

The automation control system can also introduce process analysis technology (PAT) to collect quality data of the production process online and achieve product quality control. The system uses online process analysis instruments to measure the key quality parameters and performance characteristics of raw materials, materials in processing, and the process in real-time, in order to design, analyze, and control the production and processing process, accurately determine the quality status of intermediate and final products.

In addition, machine vision recognition systems and industrial robots provide new possibilities for automation control systems in pharmaceutical companies. The machine vision recognition system uses machines to replace human eyes for measurement and judgment, simulates human visual functions by capturing images through computers, and extends human visual perception. Observe the situation on the production site through machine recognition, and judge and classify the results. Industrial robots combined with robotic arms and automatic conveying technology achieve modular and intelligent production processes, improve production efficiency, and enhance the working environment in workshops.

In order to facilitate the deep mining and organization of data in the later stage, a Plant Information System (PI) application platform should be added to the automation control system as a large real-time database and historical database. Used for automatic collection, storage, and monitoring of factory data. This application platform provides clear and accurate operation screens, allowing users to browse the current production situation of the factory and review past production situations. Provided fast and efficient factory information for end-users and application software developers, facilitating relevant personnel to improve processes, implement comprehensive quality management, and perform fault prevention and maintenance. (Excerpted from the White Paper on Intelligent Manufacturing in China's Pharmaceutical Industry (2020 Edition), jointly compiled by the Industrial Development Promotion Center of the Ministry of Industry and Information Technology and the China Pharmaceutical Enterprise Management Association)

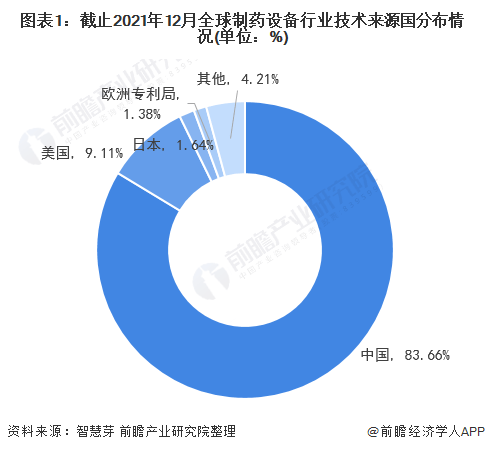

Prev:Analysis of the Competitive Landscape in the Pharmaceutical Equipment Technology Market: Only Xin En

Next:The Pharmaceutical Industry Digitization Summit is held, and experts and scholars discuss the develo

CN

CN  EN

EN